Functional 3D Printing

3D printing is a fun hobby. It’s also a great way to solve a lot of problems around the home. Here’s a quick tale about how I used 3D printing to solve a problem I had with my car.

Mazda 2007 MPV Ignition Switch

I had a problem.

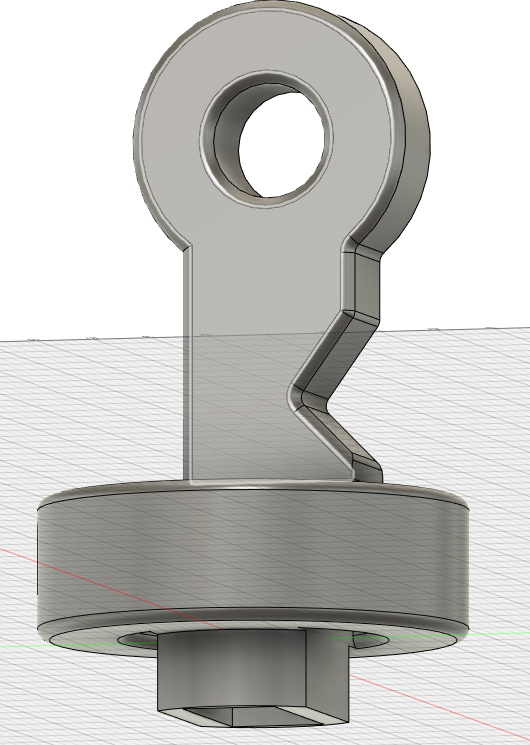

My car’s ignition switch was broken. The plastic part that covers the key hole snapped. In itself that’s not a problem because the key can still be used to start the car.

Unfortunately, I lost that too.

I was left with a the fob and a switch I was unable to turn.

Lucky for me, I have a 3D printer.

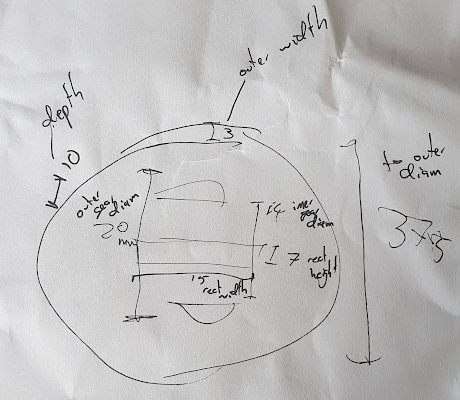

Measure it

The part was pretty straight forward and used very straight forward shapes. I used a pair of calipers to measure all the dimensions of the switch and scribbled them down on a piece of paper.

I actually missed the depth of the part so I had to print it twice. The first time it was too shallow.

Design it

I used Fusion 360 to design the piece. It’s a free tool for hobbyists and students. It’s also a very powerful tool that I had used at University so the learning curve was very low.

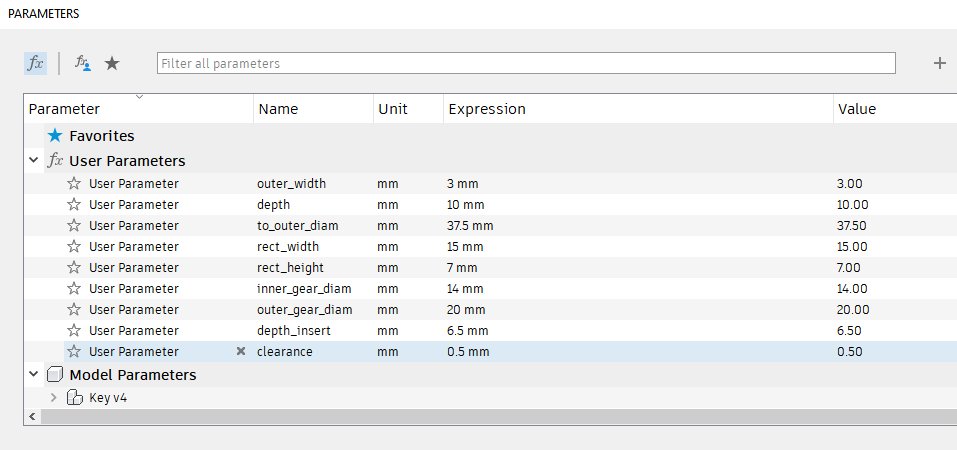

Protip: I store all the dimensions as parameters in the design so I can easily change them later. This was very useful when I had to print the part a second time as it only took a few minutes to adjust the design.

Print it

I used a Creality Ender 3 V3 SE to print the part. It’s a great printer for the price and I’ve had a lot of fun with it.

Share it

As a strong supporter of open source, I always make sure my designs are available for others to use.

You can download the STL file right here or from Thingiverse, which also has all my slicer settings.

Thanks for reading

If you enjoyed the content please consider leaving a comment, sharing or hiring me.

Cheers,

Michael

Twitter Facebook Google+

comments powered by Disqus